Modules for Turnaround

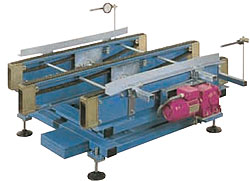

Pallet transfer unit with lifting chain section

The pallet transfer unit with lifting chain segment can be delievered with two or multitrack chain conveyors on request in two length 1400/1800 mm. The motor-driven pallet lifting equipment of the chain segment ensures an optimum composition of the pallet. Pallets have an unchecked passage possibility. Very compact, space-saving design.

Pallet transfer unit with lifting roller section

The pallet transfer unit with lifting roller segment can be delievered with two or multitrack chain conveyors on request in different lengths starting with 1400 mm. The motor-driven pallet lifting equipment of the roller segment ensures an optimum composition of the pallet. Pallets have an unchecked passage possibility. Very compact, space-saving design.

Turning corner station

The rotating corner composer has a rotating combination unit with roller lifting offset and chain haulages for optional transport with longitudinal or transverse run during processing different pallet sizes and shapes. It offers an absolutely safe entry and exit even for extremely bent pallets and projecting foreign bodies through increased lift. The chain is tensible by spindles. The rotating corner composer has a secured, fixed limit switch position through a fixed, vibrationless sensor holding device.

Turntable station

Turntables with roller conveyors and chain segments connect paths located rectangular to each other. The possibility for longitudinal and transverse pallet run is given. The rotating frames hare mounted on rolling bearings. The load distribution is circular via four carrying rollers. Switch gear, sinusoidal 90° rotations ensure exact stops through a slider-crank drive. A central drive on the path segment can be delivered for a rotation angle up to 270°, on request.

Combined turning station

Rotating station for longitudinal and transverse pallet run. It has a rotating connection between 15° and 270°. An easy rotation via a friction wheel enables exact holding positions. The circular load distribution is via four plastic rollers on a stable base frame with central mounting on rolling bearings. The safety aprons located around prevent any inadvertent access. Due to this, additional protective gratings are omitted.

Pallet lifting platform

The pallet lifting platform is used for transporting empties, full or pallet stacks up to 4.5 m lifting height as vertical transporting means for several stops with small and medium transport level differences. The design can be realised as L or U shape in a two-column design. The lifting cage for the U shape can be equipped with roller conveyors or chain segments and the L shape with roller conveyor rotating segment, chain rotating segment as well as corner composer. By this, the direction of the material to be transported can be changed. The drives can be mounted at top or bottom. Depending on design, the weight equalisation for lifting platforms is established with or without counterweight. The drive operateswith pole changing or frequency regulation depending on the performance desired.

Pallet elevator

The elevator is used as vertical transporting means for several stops. Entry and exit of the pallets can take place from all sides with the same axial direction. The case components may optionally include roller segment, chain segment or turning corner station. The cage weight iy by far compensated by counterweights. At elevator top the lifting drive is installed with the fine motion gear-box. This gearbox ensures an exact positioning of the cage at the individual stops. The frame of the lift is in galvanised design and lined with woven mesh. The design as double elevator enables the simultaneous transport of two pallets one after another. The lifting device as chain design is single or double conveyor depending on performance.